Printed circuit boards (PCBs) are an essential component in modern electronic devices, including displays and sensors. However, the traditional manufacturing process for PCBs generates significant amounts of liquid waste and high carbon emissions. Fortunately, innovative technologies and companies like Tokyo-based startup Elephantech are working towards a more sustainable future for PCB production.

The Environmental Impact of Traditional PCB Manufacturing

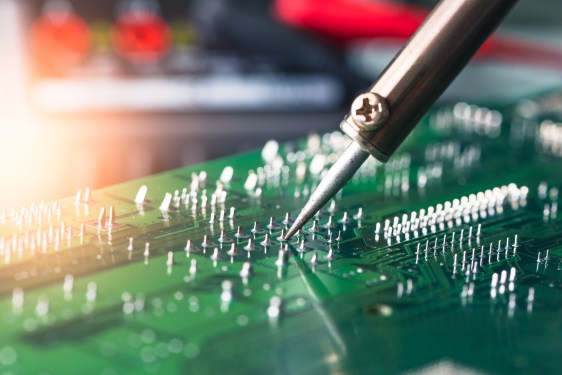

Traditional PCB manufacturing processes involve layering an entire surface with metal before dissolving the areas that aren’t necessary. This subtractive method results in substantial liquid waste and high carbon emissions. According to various estimates, the production of traditional PCBs accounts for approximately 3-5% of the world’s annual CO2 emissions.

Enter Elephantech and its Eco-Friendly Solution

Elephantech has developed an innovative eco-friendly PCB called P-Flex using inkjet printing-based electronic circuit manufacturing technology. This approach reduces carbon emissions by 77% and water consumption by 95% compared to conventional processes. The main difference in Elephantech’s process is that it uses a ‘pure additive’ method, where metals are only placed where they are needed, eliminating the need for subsequent removal (i.e., waste).

The Benefits of Additive Manufacturing

Elephantech’s nanoparticle inkjet technology not only reduces carbon emissions and water consumption but also cuts costs by 32%. This is achieved by removing several procedures from the manufacturing process. The company’s additive approach has far-reaching benefits, including:

- Reduced material waste

- Lower energy consumption

- Increased production efficiency

Meet Elephantech’s Mission: Sustainable Manufacturing

Elephantech’s mission is to create a sustainable world through resource- and energy-efficient manufacturing technologies. To achieve this goal, the company has secured 2.15 billion yen (~$15 million) in funding at a 12.3 billion yen ($88 million) valuation. This investment will help Elephantech scale its business from R&D and its current production volume to target customers globally.

Elephantech’s Plans for Expansion

The startup has already started mass-producing PCBs two years ago in its Nagoya facility, focusing on single-sided flexible substrates. However, it plans to produce multi-layered and rigid PCBs, which constitute different layers, including a copper layer, substrate layer, and silkscreen layer. Elephantech’s inkjet printing technology can also be applied to other sectors such as healthcare, optics, and textiles.

A Growing Movement Towards Sustainability

Elephantech is not the only company working towards sustainable PCB production. Other startups like Celus and Luminovo are addressing different aspects of the PCB design process, including automation and waste reduction. This growing impetus to optimize and improve on a technology that powers just about every electronic contraption there is, from smartphones to microwave ovens, indicates a promising future for companies like Elephantech.

Investors Backing Elephantech’s Vision

The company’s funding round included investments from prominent organizations such as Anri Vc, Insight Partners, and others. This support highlights the growing recognition of the importance of sustainability in manufacturing processes.

A Bright Future for Sustainable PCBs

As companies like Elephantech continue to push the boundaries of sustainable PCB production, it is clear that a more environmentally friendly approach is not only possible but also necessary. With innovative technologies and a commitment to sustainability, we can create a better future for our planet and its inhabitants.

Sources:

- "The Environmental Impact of Traditional PCB Manufacturing"

- Estimated CO2 emissions from traditional PCB production

- Elephantech’s website and press releases

- Details on P-Flex technology, funding, and company mission